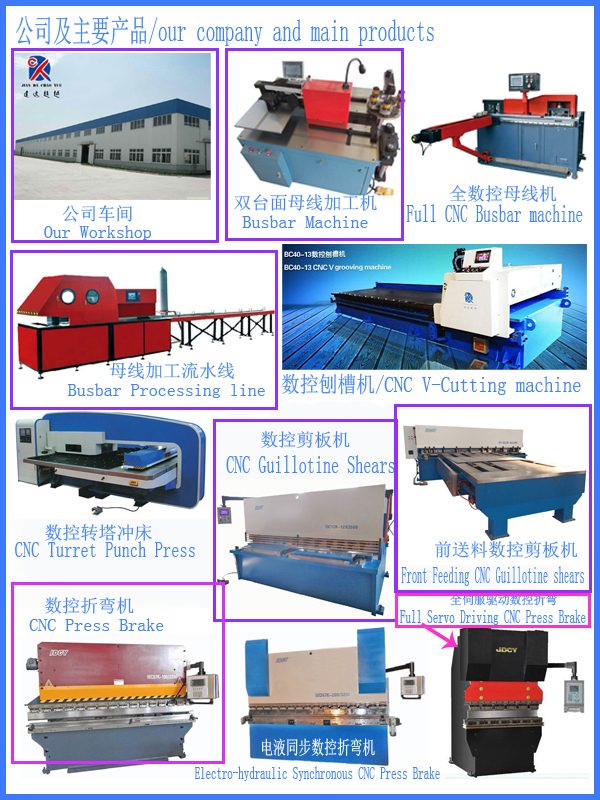

PBM-300 portable busbar machine

Details

Details

1, Name: PBM-300 portable busbar machine

2, Pictures:

3, Video link:

4, Main Functions: PBM-200 portable

busbar machine is mainly used for processing different specification of copper or aluminum busbar. Only choose the related working unit, the user can do processing work of punching, shearing, bending with high efficiency. It is ideal and necessary equipment of electric manufacturing industry, like high and low voltage switch cabinet, transformer. Etc.

5, The Main characteristics:5-1, There is 3 working units of punching, shearing and bending. It can be used for busbar punching, shearing and bending work. Through adjust and change quick connecting head, the 3 working unit can shift quickly.

5-2, This machine operated easily, used conveniently. Generally, the mature workers can use and operate it easily.

5-3, It adopts vertical processing method of punching, shearing and bending unit. They are flexible and convenient. They can be both in group and divided usage. It is very propitious to electric urgent repair.

6, Main specification parameters: | Punching unit | Punching zone | mm | Phi 7-21 |

| Cylinder pressure | KN | 200 |

| Max. width | mm | 150 |

| Max. thickness | mm | 12 |

| Bending unit | Max. width | mm | 150 |

| Max. thickness | mm | 10 |

| Cylinder pressure | KN | 150 |

| Cylinder stroke | mm | 160 |

| Shearing unit | Shearing pressure | KN | 200 |

| Max. width | mm | 150 |

| Max. thickness | mm | 10 |

| Hydraulic system | System high voltage pressure | MPa | 63 |

| Main motor power | KW | 0.75 |

| Oil tank capacity | L | 10 |

| Oil tank valid capacity | L | 7.6 |

7, Price and payment term: 7-1 price:

Contact with me forwardly. There is discount price for you!

7-2 payment term: (ESCROW payment is safer and convenient for you)

30% deposit and the balance paid before delivery by T/T.

8, Delivery time: 10 days after received the 30% deposit by T/T.

9, ISO9001-2008 and CE Certificate:

10, Package details

Office Tel:

Office Tel:  Office Fax:

Office Fax:  E-mail:

E-mail:  Address:

Address: