Details

Details

1, Name: RX Coil Winding Machine

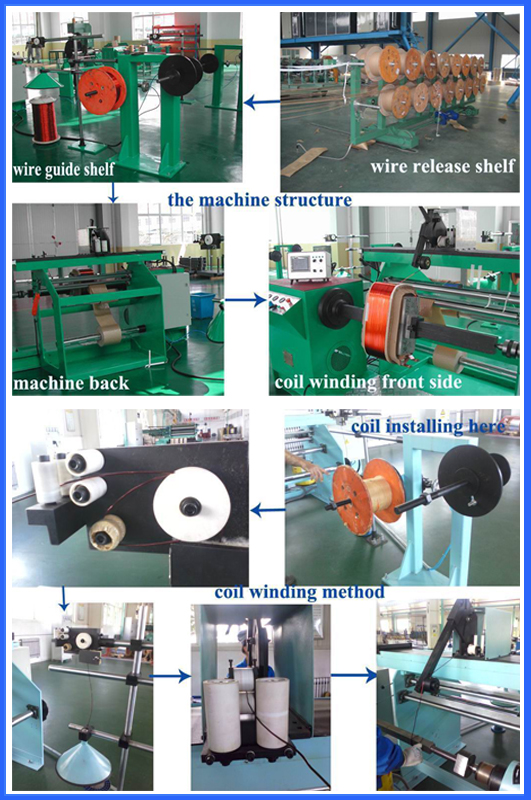

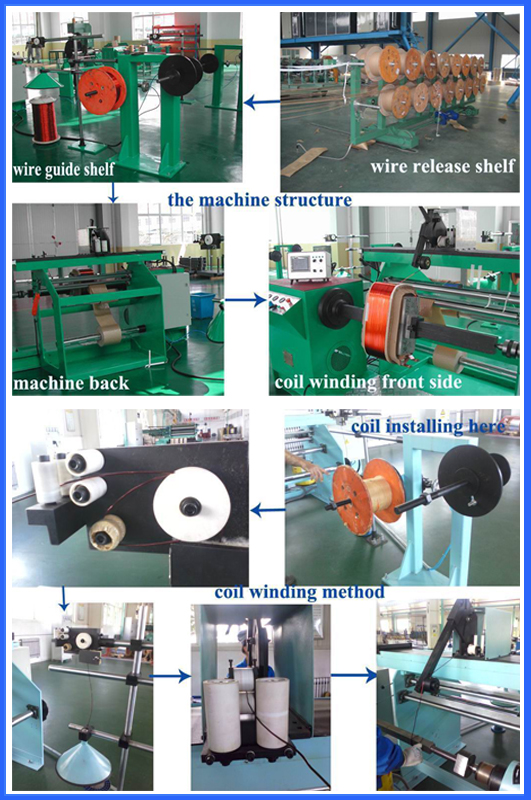

2, Picture and instruction:

Our RX series

coil winding machine has passed ISO9001:2008, CE certificate. And at the same time, it is passed test of Chinese exporting government and authorize us to exporting.

Instruction

Based on client requirement and advantage of

coil winding machine both home and abroad, we designed and manufactured this horizontal coil winding machine. This kind machine is unique, professional, esay operating, digital showing and get high praise from user. This machine is widely used in electric transformer, electic motor coil industry, etc. many famous companies have use our machine like Toshiba of Japan, Luneng electrics, etc. big electric industries.

3, Video link: 4, Model and specification | No. | Item | Parameters |

| 1 | Type | RX-1 | RX-2 | RX-3 | RX-5 | RX-10 |

| 2 | Max bearing weight(kg) | 1000 | 2000 | 3000 | 5000 | 10000 |

| 3 | Main axis rotation(r/min) | 0-150 | 0-150 | 0-60 | 0~30 | 0~15 |

| 4 | Main axis height(mm) | 800 | 800 | 1100 | 1400 | 1400 |

| 5 | Motor power(Kw) | 3 | 4 | 5.5 | 7.5 | 15 |

| 6 | Distance between main axisand end box(mm) | 800-1500 | 800-1600 | 1000-2500 | 1500-3000 | 1500-3500 |

| 7 | Diameter of disc(mm) | 400 | 400 | 600 | 800 | 1000 |

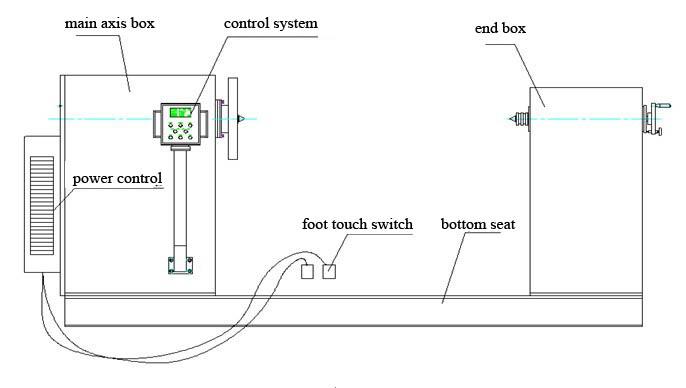

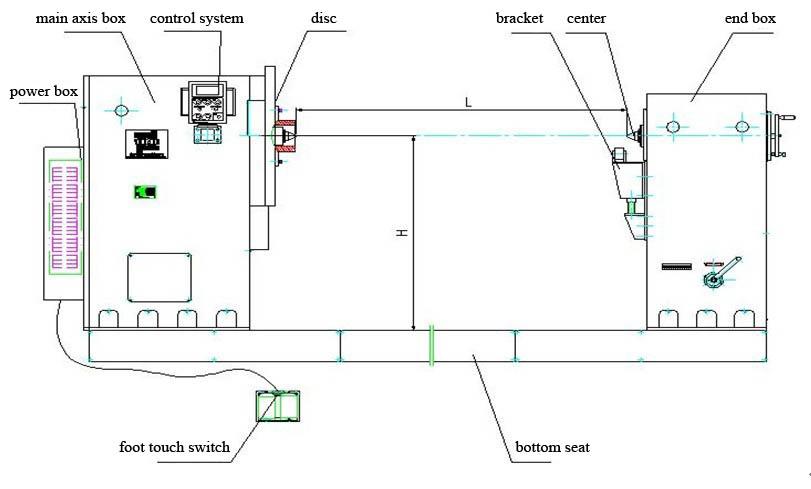

5, Design description: outline of whole machine This horizontal coil winding machine is mainly made of main axis box, end box, bottom seat and control system(check the following picture)

horizontal coil winding machine RX-1, RX-2, RX-3, RX-5

RX-10H horizontal coil winding machine

Main parts and bottom seat are together, end box can be moved easily and quickly, which can keep accurate of front and back axis and the same height. When we do the coil winding work, the machine is operating smoothly, the quality is improved.

5.1 main axis parts

Driving parts are in main axis box. Power is exported from motor and transferred to speed reducer through belt pulley, then arrive at main axis by chain, finally the coil winding mould is rotated by winding connection disc in the front of main axis.

This part is mainly composed by main axis box, PLC, motor seat, motor, speed reducer, belt wheel, chain wheel, main axis, winding mould disc, etc. tightly driving method is taken between speed reducer and main axis, which and avoid slipping and keep accurate driving rate and efficiency. Electromagnetism braking motor can assure braking immediately and accurately, main axis can be locked automatically. In order to use conveniently for client, changing structure is taken in the front of main axis, coil winding mould can be changed according to client requirement easily.

5.2 end box parts

This parts is mainly composed by end box body, rack and pinion, small speed reducer, telescopic shaft, coil winding mould connection disc, etc.

The end box can be moved on seat in front and back side, loosen the bolt in both side of end box to move box according to the indicator, then tighten bolt. Telescopic axis is 0~200mm, we can modify it through handle, after finished it, tighten pins. Considering the defect of traditional coil winding machine, we make more professional design(check the following picture), which improve strength, bearing ability, shape changing highly. We use T-type screw for movement in front and back. Locking and moving are finished by handle very conveniently.

5.3 bottom seat

The bottom seat is incorporated and composed by high quality steel sheet and H-type steel, which assure the strength, accuration, prety, stability.

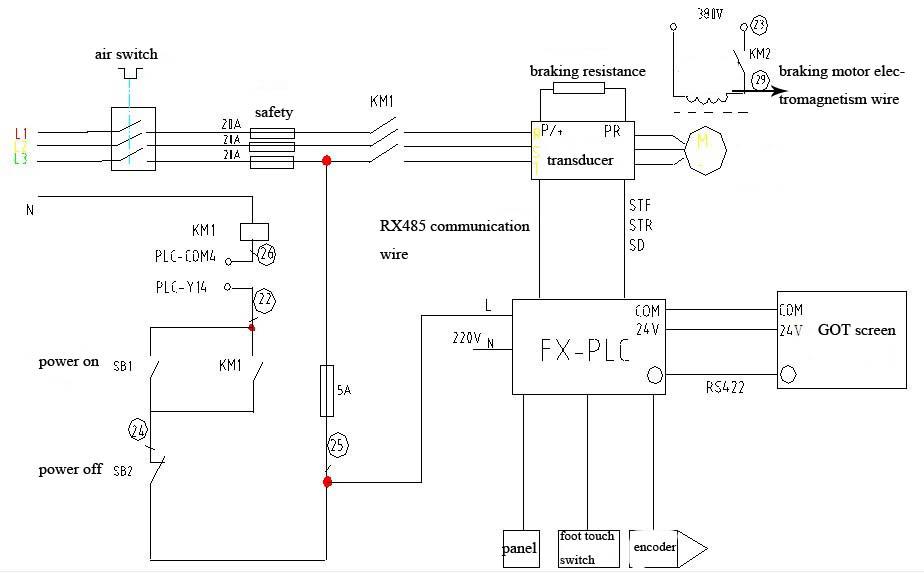

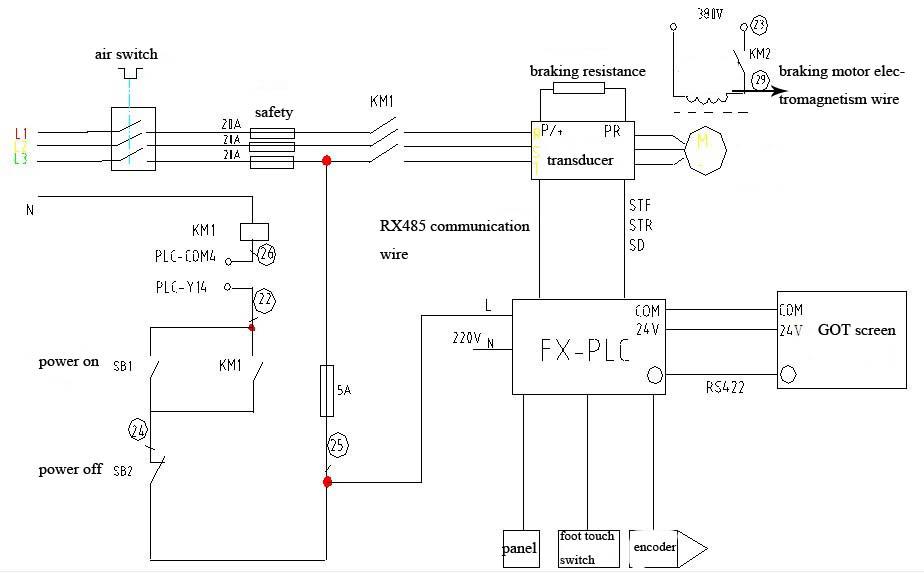

5.4 electric control parts

5.4.1 working principle

This parts is composed by power box and PLC control box. Transducer, PLC and touch screen are all imported by MITSUBISHI of Japan, Siemens of Germany, and so on.high quality and famous brand.

Electric part is composed by machine loading system and measure control part: machine loading system control transducer through PLC to achieve controlling speed; measure control part is encoder note the main axis speed, then the data is dealed with and sended to touch screen. It can memery in electri stopping and data adverse.

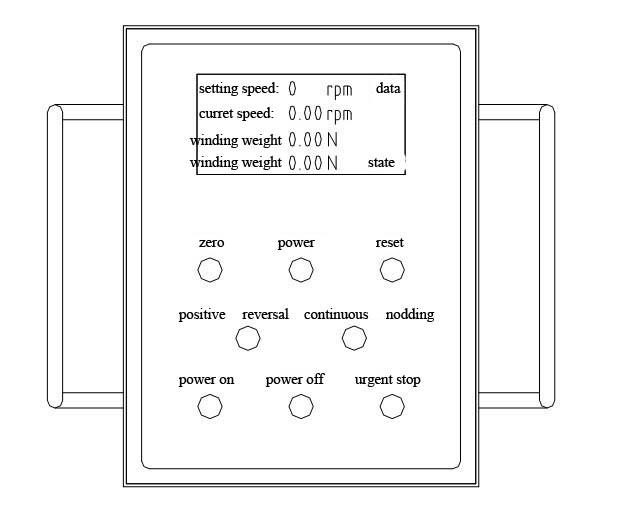

5.4.2 function of operating panel

Operating panel content is as following:

First, turning on the main power of air switch in power box, then the screen can display.

1) power on button: pressing power on button to start transducer, light of power on open.

power off button: pressing power off button to turn off transducer, light of power off open.

2) nodding/continuous button: making the button in nodding state, pressing foot switch to start motor, loosening foot switch to stop motor; making the button in continuous state, winding continuously, pressing again to stop.

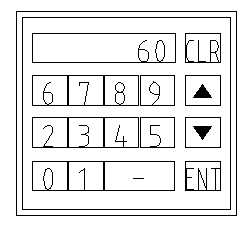

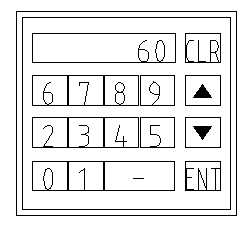

3) speed setting function: touching screen item “setting speed” number 0(it is present speed), it displays like following.

Input your required speed, for example 30, then press ENT, and press confirm,the speed is in effect.

4) positive/reversal state: there is 2 methods for your choice: pressing foot switch to exchange positive and reversal state and using button in panel to exchange the 2 state.

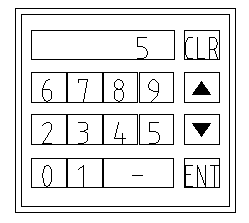

5) number of windings: this function is convenient for user, if client want to make winding in the same direction continuous, you can choose the function 0.00, like the following picture.

Input the required number of winding, for example, inputing 5.00, then press ENT, the motor starts, when the machine finished the setting data, it will stop automatically. When you input negative number, there is no effect.

(setting number of winding is adding or reducing based on the present data).

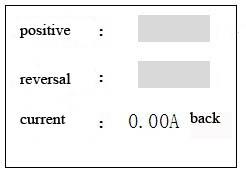

6) state of screen

This function is designed to check the working state of motor, when the machine works in normal sate, the light of positive or reversal will flicker. Current item can show the present current data, if the date is higher than the max of motor, transducer can protect it, motor stop automatically. Checking machine and restart again.

7) zero button: if you want to make the present winding number to zero, pressing it in 2 seconds.

8) urgent stop: if there is abnormal work happened, pressing urgent button, machine will stop slowly, checking machine and restart again.

6, Performance and working environment6-1 performance:

1) reliable working, convenient operation; starting and braking smoothly.

2) positive and reversal winding can be achieved by foot switch and control box. Screen can display the winding number of positive and reversal, and remember the data when the electric stops.

3) parts of machine are standard and bought from formal manufacture. Transducer, PLC and screen are all imported from famous and high quality foreign companies.

4) safe and reliable working; flexible operating, no blocking.

5) outline is tidy and prety.

6-2, working environment

Normal working environment

1) right installation on steady foundation

2) clean environment without vibration, corrosion and strong electromagnetism.

3) power pressure zone should not be over the setting press ±10%

7, Configuration 7.1 machinery part

| Name | Manufacture | Note |

| Chain | Qingdao | Main axis driving |

| Qiangzhu speed reducer | Zhujiang | Moving end box |

| Speed reducer | Guomao | Main axis speed reducing |

| Deep groove ball bearing | Haerbin bearing | Moving end box |

| Cone roller bearing | Haerbin bearing | Main axis, end axis loading |

7.2 electric control part

Main component and supplier

| Name | Supplier | Note |

| Transducer | Mitsubishi | |

| Programming controller PLC | Mitsubishi | |

| Touching screen | Mitsubishi | |

| Encoder | Shanghai | |

| Electromagnetism 3 phase asynchronism motor | Wannan motor | |

| Foot switch | Taiwan | |

| Power button | Schneider or DELIXI | |

7.3 technology documents

Including: coil winding operation manual, transducer operation manual, certificate of quality, packing list.

8, Assurance after selling and technology secret agreement: 8-1, assurance after selling

Guarantee time is 1 year after delivery. If there is any machine problem happened in the time, supplier should repair it in time. For the parts not destroied by workers shoud change freely. Out of guarantee time, if there is a problem for the buying machine, client should inform supplier in time, manufacture should supply service according to client requirement after communication.

Based on the above situation. Our company want to give your our best wishes for your development, we will use our best quality and favorable price to establish long time cooperation with you.

8-2, technology secret agreement

1) this technology is belonged to our company. Client should keep secret for our supplying document and information and have responsibility for keeping secret, whether this method is taken or not, this rule is in legal long time.

2) our company also have responsibility for keeping secret of the document and information supplied by client.

9, Price and payment term: 9-1 price:

Contact with me forwardly. There is discount price for you!

9-2 payment term: (ESCROW payment is safer and convenient for you)

30% deposit and the balance paid before delivery by T/T.

10, Delivery time: 20 days after received the 30% deposit by T/T.

11, ISO9001-2008 Certificate: 12, Structure of machine

Office Tel:

Office Tel:  Office Fax:

Office Fax:  E-mail:

E-mail:  Address:

Address: