Details

Details

1, Name: GRX-800 Automatic Cabling Coil Winding Machine

2, Picture and instruction

Our GRX-800 automatic cabling

coil winding machine has passed ISO9001:2008, CE certificate. And at the same time, it is passed test of Chinese exporting government and authorize us to exporting.

Instruction

GRX horizontal type

coil winding machine is designed and manufactured by our company, based on the requirement of client and advantage of home and abroad. This type machine is unique and novel, operated easily, displaying directly. It is best seller in the market. At present, this machine is used widely in electric transformer industry, for example, Toshiba of Japan, Wolong of Yinchuan, Sanbian of Zhejiang, etc.

our advantage and using range

Our GRX-type automatic coil winding machine is widely used in CF and dry transformer. At present, we have received high praise from our client in home and abroad like Xian Xidian transformer, Baoding Xiaoxing Tianwei transformer, Toshiba of Japan, etc.

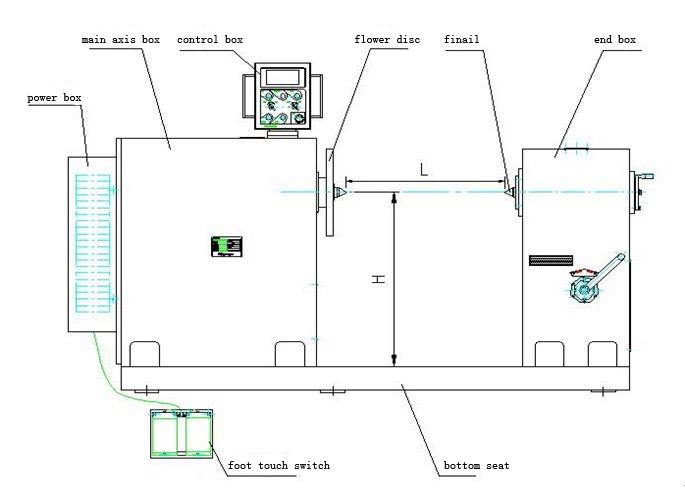

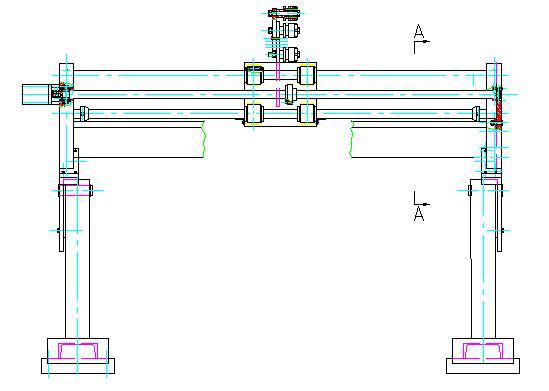

3, Video link: 4, Design drawing: GRX coil winding machine composition

This type horizontal coil winding machine is main composed of main axis box, end box, bottom seat, automatic winding and control part.

Automatic coil winding machine outline

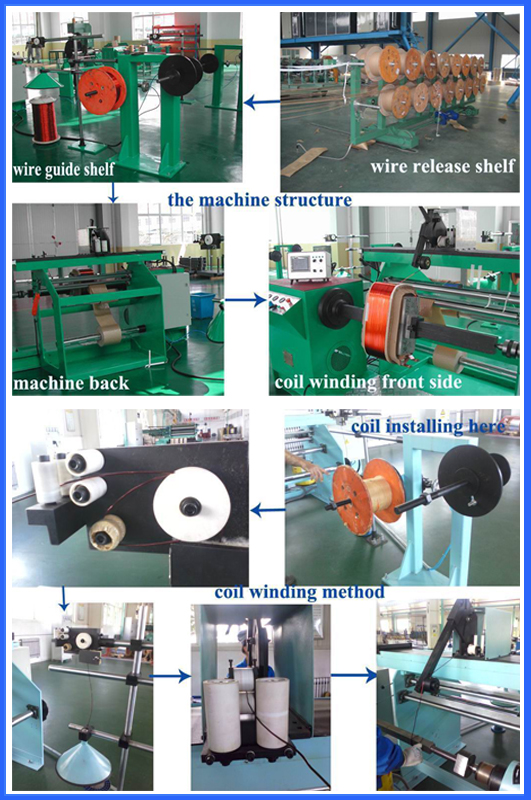

Automatic coil winding machine coil shelf picture

5, Main technology index and performance 5-1 main technology index

| No. | Item name | Index |

| 1 | Product type | GRX-800 |

| 2 | Max bearing weight(kg) | ≤1000 |

| 3 | Main axis speed(r/min) | 0~570 |

| 4 | Main axis center height(mm) | 850 |

| 5 | Winding axis center distance(mm) | 500~1250 |

| 6 | Motor power(kW) | 4 |

| 7 | Rectangle coil diagonal length(mm) | ≤800 |

| 8 | Working voltage AC (V) | 220±10%, 3 phase, 60HZ |

| 9 | Air pressure(bar) | 5-6.5 |

| 10 | Using range | Outer dia.≤600mm,inner dia.≥80mm |

| 11 | Max setting winding number of counting | 99999.9 |

| 12 | Round wire or sheet wire, enamel covered wire

or paper-covered wire | 2 sheet wire≤3×12mm

Enamel covered wire 0.3mm-3mm |

| 13 | Whole machine power(kw) | About 5 |

| 14 | Automatic winding function | Min. diameter of modifying wire 0.01mm |

| 15 | Stepping winding range(mm) | 0.1~5 |

| 16 | Stepping precision(mm) | 0.01 |

5-2 performance

1) this machine is reliable and easy operating. Suitable for starting smoothly, stepping continually, braking steadily and braking urgently.

2) main axis reverse winding can be achieved by foot-touch switch and control box. The display screen can show the winding number and have reverse winding and power-off memory function.

3) winding accessory is standard and manufactured by normal factory. Transformer, PLC, touching screen are imported from high-quality factory, other accessory are home famous factory supplying.

4) this machine winding is smooth, safe and reliable. Operating handle and handwheel is flexible, no blocking. Before winding, you can set the winding distance according different specification. In the winding, you can modify according to the fact and assure the coil tight. It is suitable for rectangle and oval coil winding.

5) digital showing, you can set the winding circle number advanced and divide it into 20 sections in total winding.

6, Operating environmentCoil winding machine can operating in the following environment.

1) right installation on steady base

2) need clean environment without shaking, corrosion things and strong electromagnetism disturbance.

3) power voltage fluctuate range can’t be higher ±10% than setting voltage.

7, Whole machine configuration7-1 mechanical parts

| Item | Factory | Note |

| Chain | Qingdao | Main axis driving |

| Qiangzhu speed VARVEL | Qingdao | Used for end box moving |

| VARVEL | Changzhou and Tianjin | Main axis speed reducing |

| Deep groove ball bearing | Haerbin benring factory | End box moving |

| Cone roller bearing | Haerbin benring factory | Main axis and end axis bearing |

7-2 electric control parts

main component and manufacture

| Item | Manufacture |

| transformer | Mitsubishi of Japan |

| Can programming controller PLC | Mitsubishi of Japan |

| Human-computer interface (liquid touch screen) | Mitsubishi of Japan |

| RS-485 communication mould | Mitsubishi of Japan |

| RS-485 communication wire | Mitsubishi of Japan |

| RS-422 communicationwire | Mitsubishi of Japan |

| Photonics coder | Shanghai |

| Electromagnetism braking 3 phase synchronization motor | Wannan |

| Foot-touch switch | Taiwan |

| AC contactor | DELIXI or Schneider |

7-3 technology documents

Including: coil winding machine operation manual, transformer manual, quality certificate, packing list.

8, Coil winding machine main parts material 1) Headstock welding material is Q235-A

2) Bottom seat weldingmaterial is H-type steel, Q235-A

3) End box welding material is Q235-A

4) Main axis 40Cr after rough machining, then thermal refining

5) Slipping axix and cover 40Cr after rough machining, then thermal refining

6) Main axis clamp tools 40Cr after rough machining, then thermal refining

7) End axis clamp tools 40Cr after rough machining, then thermal refining

8) Main axia body, end box and seat are welded by high quality steel and CO gas shielded arc welding. After aging, then to finished parts. Welding quality and precision are high, which can assure the whole machine operating smoothly and reliable.

9, Price and payment term: 9-1 price:

Contact with me forwardly. There is discount price for you!

9-2 payment term: (ESCROW payment is safer and convenient for you)

30% deposit and the balance paid before delivery by T/T.

10, Delivery time: 20 days after received the 30% deposit by T/T.

11, ISO9001-2008 Certificate:

12, Structure of machine

Office Tel:

Office Tel:  Office Fax:

Office Fax:  E-mail:

E-mail:  Address:

Address: