Details

Details

1, Name: QS-QC12K CNC front feeding Shearing Machine

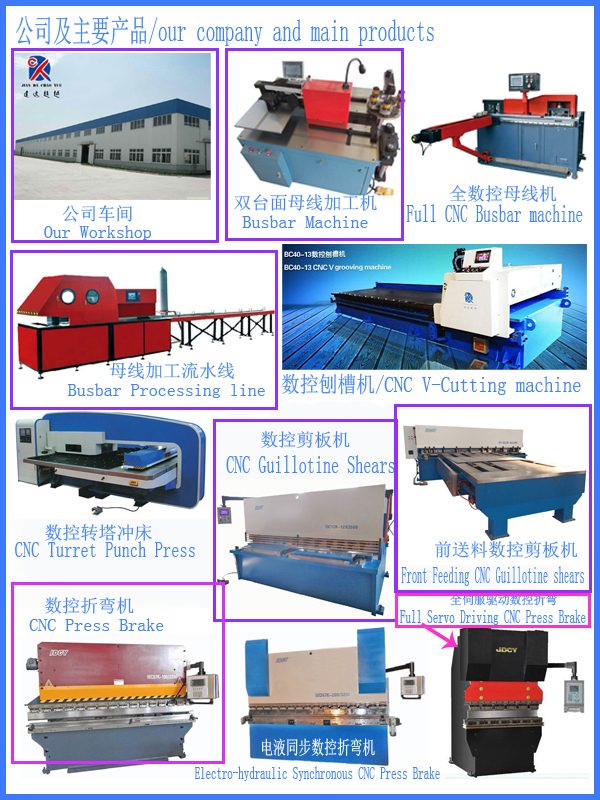

2, Picture and our power(certificate) Our QS-QC12K CNC metal cutting machine has passed ISO9001-2008, CE certificate, and the machine also passed Chinese government exporting quality assurance quality certificate. 4 years gold supplier in alibaba website.

3, Video link: 4, Instruction:CNC shearing machine is also called CNC cutting machine, hydraulic CNC shearing machine, guillotine shearing machine, plate shearing machine, metal sheet shearing machine, which is main used for cutting and shearing steel sheet.

This machine is mainly used for shearing and processing of metallic board in the industries such as machinery manufacture, high or low pressure switch cabinet, household appliance, automobile, grain machinery, medical appliance, kitchen equipment, light industry, textile machinery, chemical machinery, ship making, stainless steel decoration and so on.

5, Main Characteristics:5-1, Hydraulic transmission, swing knife rest. The overall welding structure of machine frame is firm and durable.

5-2, With the function of rapid adjustment of blade gaps, reliable location.

5-3, Adopted the device of stroke adjustment which to be convenient and rapid stepless control.

5-4, High precision ball screw and linear guide.

5-5, material feeding, return, shearing work are automatically.

5-6, pneumatic clamp for metal sheet feeding and return, no need manual operation.

CNC system is imported from Dutch DELEM originally and completely, Which has function of revision and conceding and so on. LED display, convenient and simple to operate.

Advantage:

1, the most advanced CNC control system, DELEM of Holland.

2, the back gauge is used the highest accurate guide to assure shearing precision.

3, material feeding worktable automatic feeding, return, clamp, no need manual operation.

6, Technical Parameters: | Machine model | Max Shearing

Thickness(mm) | Max shearing

width(mm) | Shearing

angle | Stroke time

(time/Min) | Motor

Power (KW) | Machine weight(T) | Machine size

L×W×H(mm) |

| QS-QC12K-4x2500 | 4 | 2500 | 1°30′ | 12 | 5.5 | 6 | 3085×4740×1550 |

| QS-QC12K-6x2500 | 6 | 2500 | 1°30′ | 12 | 7.5 | 8 | 3130×4830×1600 |

| QS-QC12K-6x3200 | 6 | 3200 | 1°30′ | 10 | 7.5 | 9 | 3840×5110×1620 |

| QS-QC12K-8x2500 | 8 | 2500 | 1°30′ | 10 | 7.5 | 10.5 | 3700×5110×1620 |

| QS-QC12K-8x3200 | 8 | 3200 | 1°30′ | 8 | 15 | 12.5 | 3880×5120×2125 |

Note: material intensity: σb≤450KN/mm2; No. of stroke A/B(e.g:15/12) indicate:

A means No. of ram strokes of CNC shear with CNC back gauge.

B means No. of ram strokes of CNC shear with CNC front feeding when feeding-in 600mm long board.

Front feeding table technical:

Max stroke

(mm) | Max speed

(m/min) | Location

precision(mm) | CNC front feeding | Weight

(T) | Dimension

(LxWxH)(mm) |

| L(mm) | W(mm) | T(mm) |

| 2500 | 15 | ±0.1/300 | 10-2500 | 200-2500 | 1-12 | 1.2 | 3300x2500x800 |

7, Accessories list or configuration7-1, configuration

| CNC control system | DELEM310 Holland |

| Display | High definition LCD display, pixel 275x48 |

| Driving | AC servo motor(Panasonic of Japan) |

| Guide screw | Ball screw(PMI of Taiwan) |

| Guide | High precision straight line guide(PMI of Taiwan) |

| Feeding device | CNC front feeding table (stainless table with turning board) |

7-2, configuration

| No. | Name | Specification or model | quantity | remark |

| 1 | CNC front feeding shearing machine | | 1 set | |

| 2 | Operation instruction | | 1 book | |

| 3 | Front feeding table | 2500mm | 1 set | |

| 4 | Packing list | | 1 sheet | |

| 5 | Quality certificate | | 1 sheet | |

| 6 | Foundation bolt | | 8 sets | |

| 7 | Sealing ring | | 1 bag | |

| 8 | Foot-touch switch | | 2 pcs | |

| 9 | Door locked key | | 1 set | |

| 10 | Switch key | | 1 set | |

| 11 | oil filler | | 1 pc | |

| 12 | oil filler pipe | | 1 pc | |

| 13 | inner hexagon spanner | | 1 set | |

| 14 | Grease gun | HS87-4Q | 1 pc | |

| 15 | Side block | | 1 pc | |

| 16 | Nitrogen charged component | | 1 set | |

| 17 | Top and bottom knife mold | | 1 set | Installed in machine |

8, Price and payment term: 8-1 price:

Contact with me forwardly, there is discount price for you!

8-2 payment term: (ESCROW payment is safer and convenient for you)

30% deposit and the balance paid against the copy of B/L in 5 days by T/T

9, Delivery time: 30 days after received the 30% deposit by T/T.

10, Details of machine:

11, Certificate:

Office Tel:

Office Tel:  Office Fax:

Office Fax:  E-mail:

E-mail:  Address:

Address: