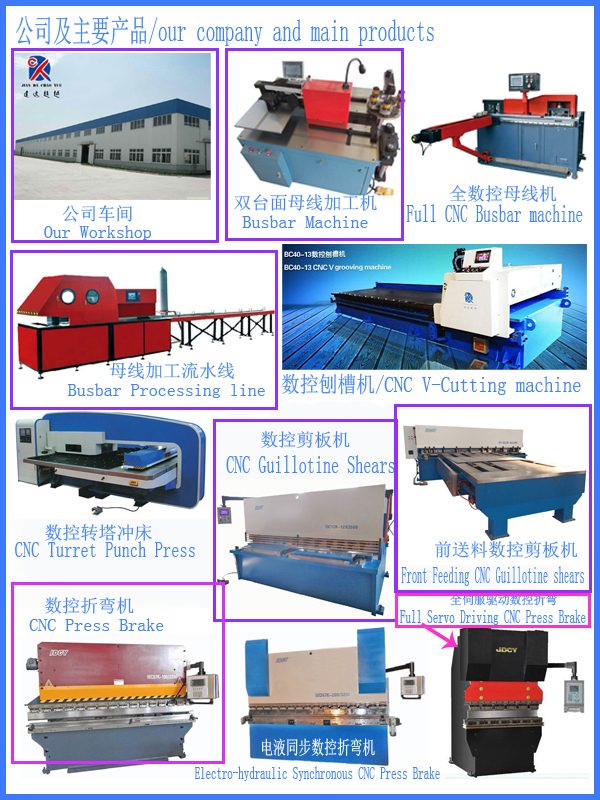

Details

Details

1, Name and model:

wsf-35/1250 Full Servo Driving CNC Press Brake (Patent number: ZL200720019824.9)

2, Picture and our power(certificate)

Our WSF-35/1250

CNC press brake has passed ISO9001-2008, CE, patent invention certificate, and the machine also passed Chinese government exporting quality assurance quality certificate. 4 years gold supplier in alibaba website.

3, Video link:

4, Instruction:CNC press brake is also called CNC bending machine, electric press brake, servo driving CNC press brake, metal sheet bending machine, Which is mainly used for processing steel sheet bending.

5, Main Characteristics:1), it is complete steel welded structure with high strength and good rigidity.

2), AC servo top transmission, stable, reliable, pollution-free, less noise.

3), Energy-saving: The power consumption is only decades of wattage when the machine is out of work.

(no work, there is no cost in electric. One year can help you save USD30000)

4), Precision of bending is high. Bending angle, back gauge size and bending pressure are controlled by CNC system.

5), CNC control system is imported from Holland DELEM originally. 4 axes for choice (Y, X, R, Z).

6), It is operated easily for adopting angle programming. the machine can be installed with MITSUBISHI CNC system of Japan with cheaper price.

6, Technical Parameters: | Model | Nominal

pressure | Workbench

length | plate Distance | Throat

depth | block

stroke | Stroke

time | operation

height | motor

power | Machine

Weight | Outline

Size |

| Unit | KN) | mm | mm | mm | mm | time/Min | mm | KW | T | mm |

WSF67K

-35/1250 | 350 | 1300 | 930 | 250 | 100 | ≥11 | 360 | 4 | 2.8 | 1300×1600×2230 |

7, Accessories list or configuration7-1, configuration

| CNC control system | Mitsubishi of Japan | TASK of Italy or DELEM DA52 of Holland |

| Back gauge driving motor | AC servo motor(Panasonic of Japan) | AC servo motor(Panasonic of Japan) |

| Back gauge guide screw | Ball screw(PMI of Taiwan) | Ball screw(PMI of Taiwan) |

| Main pressure guide screw | Ball screw(domestic) | Ball screw(domestic) |

| Back gauge guide | High precision guide(domestic) | High precision guide(domestic) |

| Back gauge | High precision minitrim back gauge(domestic) | High precision minitrim back gauge(domestic) |

7-2 accessories

| No. | Name | Specification or model | quantity | remark |

| 1 | CNC press brake | | 1 set | |

| 2 | Operation instruction | | 1 book | |

| 3 | Packing list | | 1 sheet | |

| 4 | Quality certificate | | 1 sheet | |

| 5 | Foot-touch switch | subassembly | 1 pc | |

| 6 | Grease gun | HS87-4Q | 1 pc | |

| 7 | Sealing ring | | 1 bag | |

| 8 | Door locked key | | 1 set | |

| 9 | Switch key | | 1 set | |

| 10 | inner hexagon square spanner | | 1 set | |

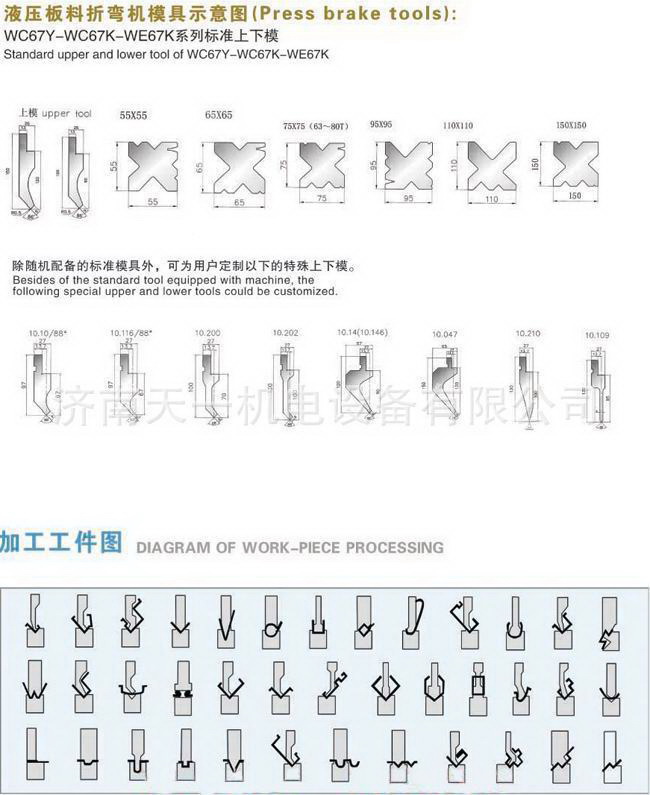

| 11 | Top and bottom bending mold | | 1 set | Installed in machine |

| 12 | Front material supporting shelf | | 2 pc | |

| 13 | Back gauge | | 2 pc | |

| 14 | Hanging ring | | 2 pc | |

8, Technical index: | X axis resolution | ±0.1 | ±0.1 |

| Y axis resolution | ±0.02 | ±0.02 |

| Max speed of X axis location (m/min) | 10 | 10 |

| Max stroke of X (mm) | 450 | 450 |

| Slide block location accuracy (mm) | ±0.02 | ±0.02 |

9, Price and payment term: 9-1 price:

Contact with me forwardly, there is discount price for you!

9-2 payment term: (ESCROW payment is safer and convenient for you)

30% deposit and the balance paid against the copy of B/L in 5 days by T/T

10, Delivery time: 30 days after received the 30% deposit by T/T.

11, Details of machine:

12, Certificate:

13, Bending indication:

Office Tel:

Office Tel:  Office Fax:

Office Fax:  E-mail:

E-mail:  Address:

Address: